He came in on Wednesday. I gathered his front brake wasn’t working. He was telling me more than that but his English wasn’t good and he was gasping for air. He looked like he didn’t have much in this world to call his own, so I adjusted his brake for free. It was a mechanical disc brake so I did the usual check. Wheel centered in the frame/fork? Yes. Lever pulls cable? Yes. Brake caliper arm actuates? Yes. Rotor is true? Yes. Wheel turns without rotor noise? Yes. Conclusion: turn the inboard pad adjuster in until the brake starts working. Ten minutes later he was out the door with a much safer bike. He graciously thanked me.

He must have liked our service and our prices because I saw him again the next day. This time he was carrying his bike. From across the shop I could immediately spot the problem.

“Why Limit Screws are Important!”

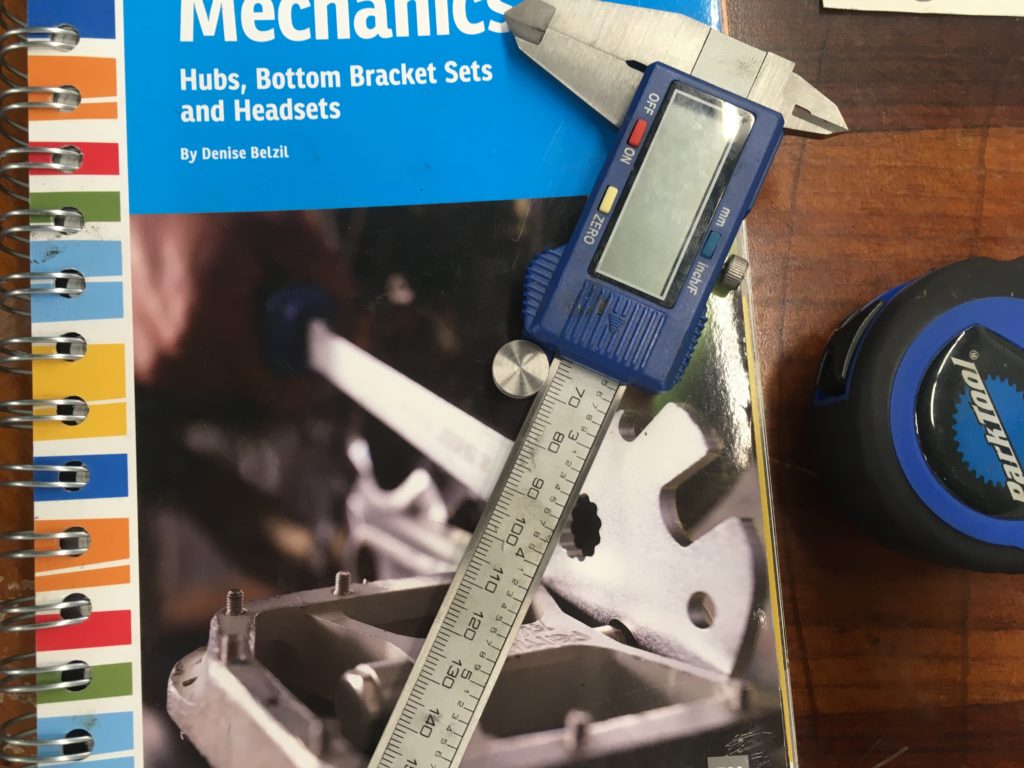

This photo was taken after I had extracted both pieces of the rear derailleur from the spokes. The derailleur hanger (silver piece) was so bent I had to unbolt it to remove the rear wheel. The chain didn’t go without a fight: the freewheel had to come off. Public service announcement to shade tree mechanics and bike shops: CHECK THE F’ING LOWER LIMIT SCREW OF THE REAR DERAILLEUR BECAUSE WHEN YOU DON’T THIS IS WHAT HAPPENS.

I told the man this was no bueno, that he’d have to leave the bike with me, and that it’d be 20 bucks to fix. (That last part was a formality to remind people that we’re not a non profit.) He left his name and phone number. I told him it would be ready in the morning.

I parked his bike until nearly the end of the day. At 6:45 pm I began to comprehend the damage. The derailleur was toast. The wheel (thankfully) was ok. The chain was a goner. The hanger was more bent than anything I’ve seen.

The organ donor displaying its new period correct XTR rear derailleur.

I had a derailleur that came off a mid 90’s K2. I had the chain — if it came to that. But the hanger? Those things are like snowflakes — their variations are endless and they are not interchangeable. I knew I didn’t have the one his bike needed and he probably didn’t have the $ pay for it anyway.

The part itself is a fairly complex shape requiring alignment along 3 axis for the derailleur to work properly AND have the piece fit the frame. The Park Tool derailleur alignment gauge can be used for simple realignments but for this job it was useless. (Also: you’re not supposed to use that tool on aluminum… because it will either break or accelerate metal fatigue.) It was time to see what the bench vise could do.

Using three nickels, then two, and finally one as an improvised mandrel the hanger began resembling its original shape. (Side note: I’d never tried this before, and figuring out this stuff is one thing I really love about being a mechanic.) It took about ten minutes from start to finish. Most of that was head scratching time.

I remounted the hanger to the bike and before installing the replacement derailleur I attempted to chase the hanger’s threads. There was almost nothing left of them. I think the derailleur was already loosely mounted before the incident. When it kicked it took the first 3 or 4 threads with it.

I cringed the entire time I was remounting the derailleur just trying not to cross thread it (and thus negating all that clever work with the bench vise). Once the wheel was back in the frame I did a little more bending. Final touches: trimming the ends of the derailleur housing loop (they were badly corroded), installing a new chain, and making DAMN SURE the derailleur’s limit screws were properly set. Finish time: 7:15 pm.

The result. I would’ve taken a better pic but the customer was in a hurry.

The guy didn’t even wait for my phone call. He showed up the next morning at ten past ten. His wheeze was worse than the day before. He explained that he had slept under the bridge. The coffee cup in his hand was bought for him by a kindhearted cop. He said the bike was his only transportation. I told him it was ready and that rather than 20 bucks the cost was 10 bucks — which would cover the chain but none of my labor. He didn’t have it. I told him he could pay me when he had the money. Once more he graciously thanked me.

Maybe I’ll see him again. Maybe not.