You gotta spend a lot of $ before your e-bike starts looking like a regular bike. For everyone else who doesn’t have $10k to drop on such a rig, behold the bike on the right… and get used to seeing more of them. No disrespect to Rad Power bikes; the RadMission is maybe the best e-bike at the $1k price point. But tons of disrespect to Cannondale for bring their thought experiment to market.

The direct to consumer model for selling bikes is here to stay. For a small shop like ours we can look at that reality in two ways: as a lost sale, or as an opportunity to provide value-added service once a box shows up on your doorstep. We see it as the latter and since opening in 2019 we have assembled Canyons, State Bicycles, and a few of the lesser known brands. We assemble the bike as if it were one of our own; we adjust the derailleurs and brakes; we true the wheels; we adjust the headset and wheel bearings; and we offer the customer a detailed assessment of the bicycle. This last part is crucial as we will help the customer file a warranty claim if something is amiss. And something often is amiss — with the exception of Canyons which are thoughtfully packaged and (even better) packaged using minimal plastic. In fact, their boxes are so good that customers hang onto them and use them whenever they need to ship a bike. The only thing that isn’t perfect is their headset design. But I’m off topic now.

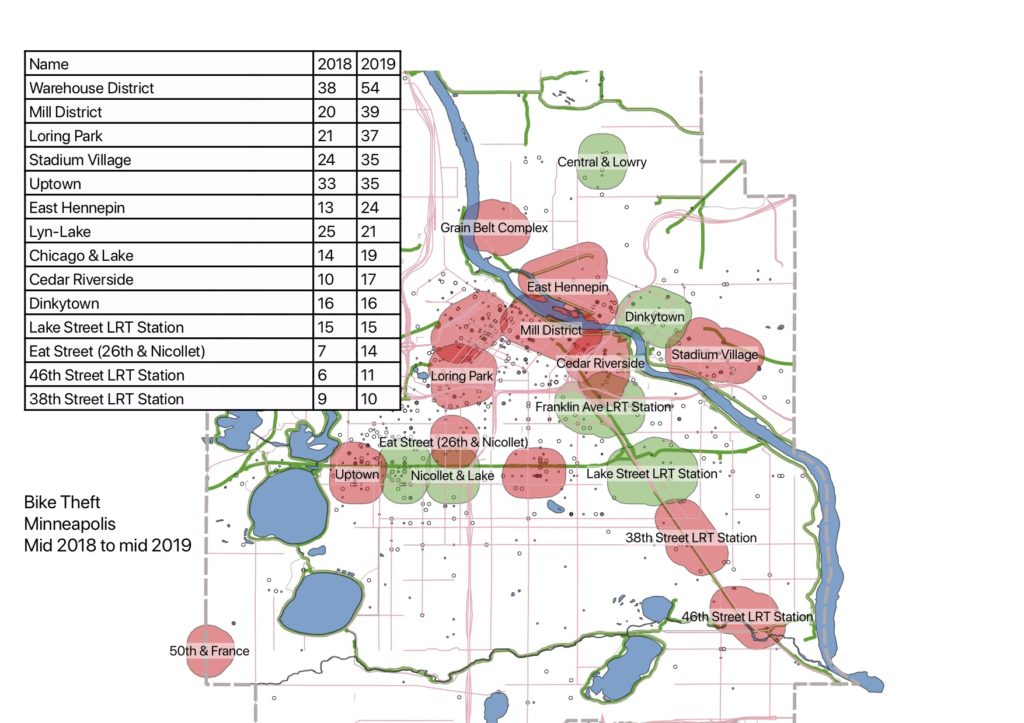

One of the direct to consumer bikes we will be seeing a lot more of is the $1,000 ebike. Ebikes for the masses is something that excites us because they have the best potential to replace car trips. Ebikes need no charging infrastructure and they will proliferate even without the generous tax credit that drivers enjoy. I have assembled a few of these and worked on a few more, so here’s the answer to what a thousand bucks buys:

- 36 – 48v battery (300 – 500 Wh) with onboard charging

- 350 – 1000 watt rear wheel based motor

- Multi-function display

- Throttle and pedal assist

- 1 x 7 speed drivetrain

- Mechanical disc brakes

- 60-80 lbs

Additional variables include wheel diameter and tire width; folding or not; and what accessories are included. What’s true of ebikes at this price point — and pretty much any ebike that’s less than $3k — is that they’re not great bikes. They’re not even good bikes because they’re equipped like a $300 mountain bike with $500 of motor and battery strapped to it. That means the shifting is going to be awful and the brakes will be even worse. And this is unfortunate because now that the motor has freed the designers of the burden of thinking about weight, they went ahead and, well, burdened the bike with weight. Should your reactor go critical mid ride, I hope, for your sake, that the way home is slightly downhill. Why slightly? See previous comment about underbraking.

Buying a $1000 ebike

Sure I spent the previous paragraph trashing the $1000 ebike, but I still think they are a good thing, and with some careful shopping you can end up with a safe bike that serves you well. Here are a few considerations:

Customer Service. This is the big advantage brick & mortar has over consumer direct sales. If I sell you a shitty bike then you can come down, get in my face, and tell me to fix it. I can’t put you into an endless customer service phone queue; I can’t ignore your multiple emails (usually submitted via a website form). Not many bike shops sell $1000 ebikes (for very good reasons) so when choosing a consumer direct brand look at the product, the product reviews, and the customer reviewers for resolving defects. Thirty day money back guarantees are great but what’s not great is shipping an 80lbs bike back to wherever it came from and hoping for your money back. I listed this consideration first because it is the most important.

Assembly. DO NOT DO IT YOURSELF. Take it to a shop, pay the money, get the piece of mind that comes with professional assembly of your underbraked landrocket. Buy a bell while you’re in the store. Seriously.

Wheel Size. There are two ways to go: conventional 700c/29er wheels or 20” wheels with 3-4” wide tires. The advantage of the former is that tire replacement, tube replacement, and spoke replacement can be done at any bike shop. The advantage of the latter is a lower center of gravity and a cushier ride. The big disadvantage of the fat and low bikes is availability of 20” x 3” tires and tubes. That back tire will wear out fast and those sizes are very hard to find under the best of circumstances. Just say no to fat tired ebikes. Trust me.

Brakes. Name brand hydraulic disc brakes are best. Look for brands equipped with Hayes, Magura, SRAM, Shimano, Tektro, and TRP. Pay extra if the upgrade from mechanical discs is an option. It is possible to find Tektro brakes and 180 mm rotors on a bike at this price point, but you will need to give up other stuff (gears). Cheap brake levers, cheap housing, cheap calipers, cheap brake pads, and cheap rotors = brakes I wouldn’t let a friend or enemy ride. That experience is the rule, not the exception.

Weight. Don’t be fooled by compact size: folding ebikes are just as heavy as regular ebikes. The only way to lose weight is paying more or simplifying the bike (see Rad Power Mission).

Motor and Range. A motor with 350 watts is plenty; a motor with 1000 watts is way too much. The more power the motor makes, the more it taxes the battery. Ride with the throttle or on max pedal assist and you will burn 25 Wh per mile. That means a 350 Wh battery will give you less than 20 miles at max power. That may be fine for most people but for a daily rider it means your battery will burn out after 2 years. I milked a 283 Wh battery for 55 miles using pedal assist 1, and pulling the twins for most of that. But I was doing a range test and trying to prove a point. Your mileage may vary.

Recommendation

After seeing what has come through our front door, and looking at what is on the market at the moment, it would seem like the Rad Power Mission is the best bike, at this price point, for most people. Why I like it: it is under 50 lbs, the motor and battery are of good power and capacity, the brakes are head and shoulders above its peers, and the brand is established. Yes, it is a single speed but most ebike owners ride in the hardest gear and dial the assist to max, so does it really matter if you have 1 or 7 speeds?

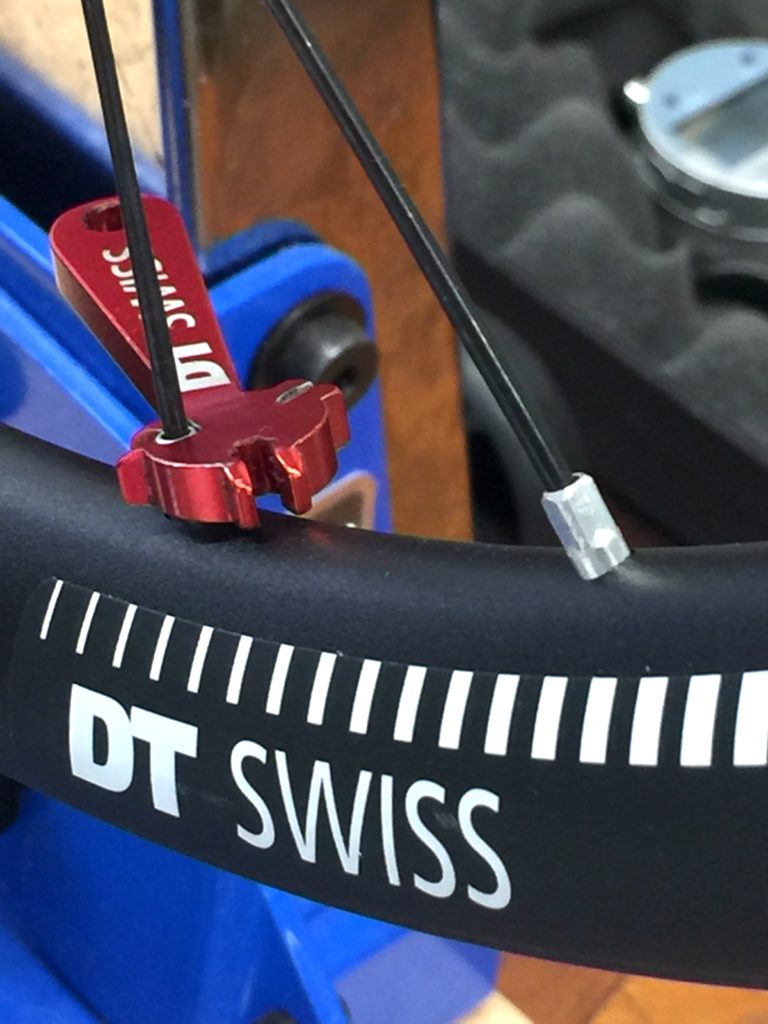

Ebikes are a relatively new thing and longevity issues are only starting to emerge. These bikes tend to be hard on drivetrains, tires, and brakes. Those items should be replaced more frequently and always with ebike rated components. OEM mid-drive systems are proving more durable than OEM wheel based systems. These motors make A LOT of torque and over time that torque will lead to spoke breakage in wheel based systems. Once that happens, that wheel needs to be returned to the manufacturer for repair, as most bike shops don’t stock the spokes and aren’t willing to deal with truing a 20 lb wheel that uses motorcycle spokes — and may be shod with a motorcycle tire. Ask me how I know. ‘We don’t have the tools to work on your bike… but you should try Erik’s!’

When you are ready to buy, come talk to me or another bike shop. We’ll talk you through the pros and cons of the various options so you can make an informed buying decision. And who knows — maybe we’ll even have something on the floor that you like!

\m/ark

Postscript

Now that you’ve searched for a $1000 ebike you will be followed across the internet by banner ads for $1000 ebike. Careful what you search for!

A

A C

C F

F G

G

I

I N

N P

P T

T V

V W

W